High performance parallel manipulator robot

Parallel robots are manipulator robots that use several kinematic chains to transmit movement. This gives them the ability to move rapidly, as the heavier components (motors) are connected to the base, while moving parts remain lightweight.

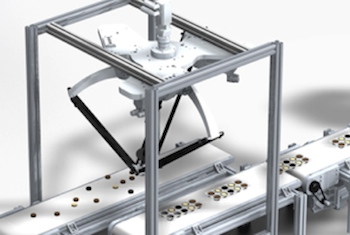

These robots are particularly well suited for industrial “pick and place” operations, which consist of grabbing, moving, and placing objects repetitively at very high speeds.

Several families of parallel robots exist for pick and place applications. The most common are 3-arm robots, using an architecture known as Delta, but 4-arm robots also exist, such as the Adept Quattro.

Engineers at the Montpellier Institute of Robotics and Microelectronics created Quattro over a decade ago.

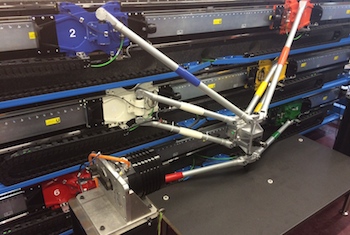

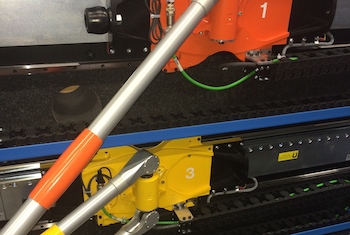

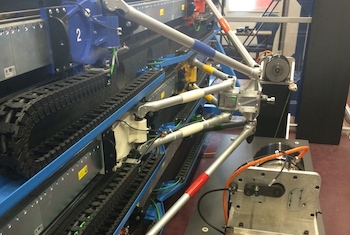

Today we are developing a new 4-arm manipulator robot for pick and place operations, offering better performance, higher speed, and a smaller footprint.

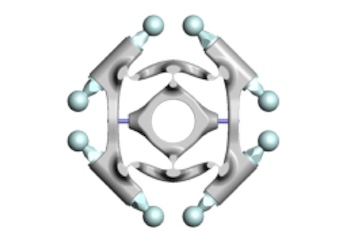

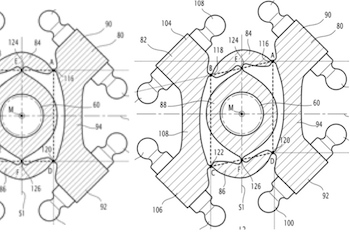

The new robot design leverages an innovative, patented architecture with a new motor arrangement and a new type of traveling plate that connects the arms with the effector.

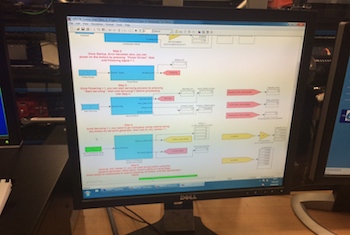

The perception system is integrated more tightly with the control system to provide better sensory response. Also, the installed vision system enables the robot to adapt on-the-fly to the type and position of objects being manipulated. In addition, generic software modules are being developed to interface the robot’s mechanical aspects with numerous types of industrial command-control systems.

This robot is developed within the scope of a partnership program involving Siléane, a French company specializing in robotics, and Tecnalia, a Spanish applied research center with offices in Montpellier.